Permeable paving, also known as porous paving, is recognised as an integral part of Water Sensitive Urban Design (WSUD), and is increasingly being employed as a powerful tool in complying with various town planning requirements for permeability, tree protection, and WSUD compliance.

But what sort of permeable paving could you use? And do you know that you don’t have to use traditional pavers? The most important feature of the pavement is that water drains through it – the rest is up to you.

As permeable paving specialists, we know a lot about the options that you can choose from. So we’ve compiled our knowledge to give you a rundown of the options. Let’s start with the main types of permeable pavers:

| Type of permeable paving | What it’s made from | How it’s permeable |

|---|---|---|

| Permeable pavers | Paving blocks, generally made of concrete | Either small gaps between pavers, or pavers are made from a permeable material |

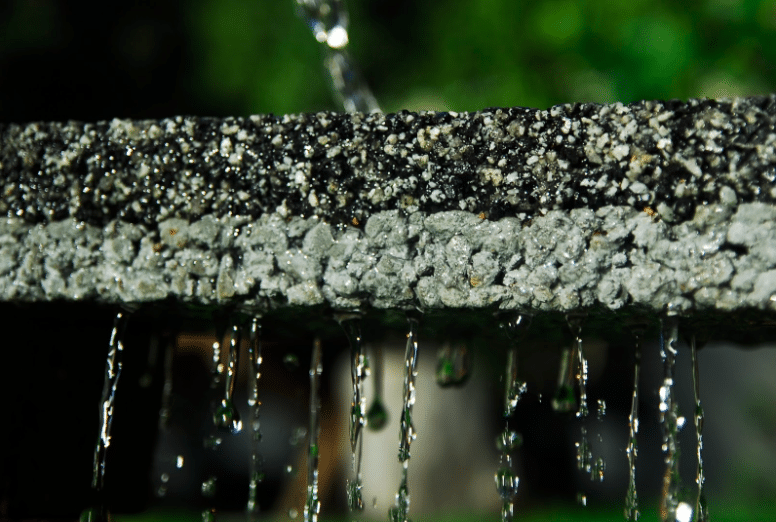

| Permeable Asphalt, or Open Graded Asphalt | Bitumen (tar, aggregate and additives) | Small gaps between the aggregate allow water to drain through |

| Permeable (or pervious) concrete | Concrete (cement, aggregate and additives) | Small gaps between the aggregate allow water to drain through |

| Resin bound permeable paving | Decorative aggregate and a UV stable resin | Small gaps between the aggregate allow water to drain through |

What are the advantages and disadvantages of different permeable paving?

| Type of permeable paving | Advantages | Disadvantages |

|---|---|---|

| Permeable pavers | Readily available, and installed in a similar manner to “normal” pavers | Normal paving techniques often don’t account for water drainage through sub grade, and movement of pavement can occur as a result |

| Permeable Asphalt, or Open Graded Asphalt | A well established material already used for freeway surfacing | Large minimum quantities apply (30+ cubic metres), no Australian Standard on what sub base to use to avoid movement |

| Permeable (or pervious) concrete | If done right, strengths rival that of “normal” concrete | Extremely difficult to finish, difficult for suppliers to batch and provide |

| Resin bound permeable paving | Highly decorative and durable finish | Difficult to work with and batch correctly, best installed by specialists |

About Permeable Pavers

Permeable pavers can be made from a variety of both permeable and impermeable materials. Some of the most popular concrete pavers are designed to form a traditional interlocking pavement with large (5-10 mm) gaps in the joints between the pavers. However, the low surface-to-void ratio, and large voids means they can readily block up with foreign matter such as tree debris and mulch.

Other pavers are made of permeable materials such as porous concrete or porous ceramics which allow water to soak through like a sponge. However, the drainage rates can be lower than other pavement types. The finish options for permeable pavers can also sometimes be quite limiting, with only a few colours to choose from, and there’s no getting away from the fact that your paving will have joints in it.

One advantage of porous pavers is that they are readily available, and marketed as being easy to install. However, the preparation of the subgrade under any permeable pavement needs to be undertaken with great care. There are subtle differences in how you install permeable paving compared to normal paving, as the constant flow of water through the subgrade can cause ground movement. (This is a concern with all types of permeable pavements, but due to the segmented nature of the pavers, localised movement can be difficult to avoid).

Permeable Asphalt (Open Graded Asphalt)

A continuous permeable surface treatment (rather than individual “pavers”) can often provide similar durability and better permeability rates. One example of a permeable surfacing treatment is Open Graded Asphalt, which is used extensively for freeway surfacing in Australia. However, (in Australia at least) it is normally laid over an impermeable, waterproofed asphalt subgrade. The permeable asphalt top surface (wearing course) is designed to allow water to drain to the side of the roadway through the asphalt, rather than on the surface. This reduces surface water, reducing spray, and improving visibility and grip in wet weather.

The major limitation of permeable asphalt is scale. Minimum order quantities, and the requirement for machine placement, means that any permeable asphalt pavements are only suited to larger civil projects. The aesthetics are also limited, with permeable asphalt looking rather like – you guessed it! – asphalt.

Permeable Concrete

In the UK and USA, widely available permeable concrete systems have been developed and are increasingly being utilised to assist with WSUD targets. Permeable concrete systems are based on “no-fines” mixes, widely used in civil works for drainage elements.

However, permeable concrete is a very different material to “normal” concrete. If supplied and installed correctly, compressive strengths in excess of 25 MPa can be obtained. However, if not supplied and placed correctly, you are left with loose gravel. Batching of permeable concrete is somewhat of an art form, and ensuring consistency of the mix throughout the pour is extremely difficult. Water addition onsite should be limited if a good finish is to be obtained.

Placing and finishing permeable concrete is equally difficult, requiring significantly different techniques and equipment to normal concrete. Even if placed correctly, the final aesthetics of the finished surface are not as good as alternatives, and surface unravelling can be expected if installed incorrectly.

Resin Bound Permeable Paving

Resin bound permeable paving uses a UV-stable resin binder (typically a strong, flexible polyurethane) to bind small decorative aggregates together. The mixture can be trowelled to a smooth finish. The final finish, if installed correctly, surpasses the best of exposed aggregate concrete. The smaller stone size and more consistent mixing and batching results in an extremely durable interlocked surface that still obtains a high void ratio resulting in excellent permeability rates.

With all porous pavement types, the final pavement performance is highly dependent on the subgrade preparation. Whilst in the UK (the home of Resin Bound paving), “road base” subgrades (e.g. crushed rock courses) are considered appropriate, the reactive soils in Melbourne make these subgrade treatments unsuitable. We recommend and only use reinforced permeable concrete as a subgrade for our permeable paving installs.

What’s the most important factor in the success of a paving install?

Numerous differences exist between the materials and installation techniques required for permeable pavements compared to “normal” impermeable pavements due to the drainage of water through the paving, subgrade and subsoil. It is essential when considering permeable paving to compare not only the paving system being used, but also the skill and experience of the installer with permeable pavements. The success of your project might just depend on it.